Our company specializes in development and production of induction heating equipments and technologies. Our excellent, highly trained engineering team and high quality production lines ensure the quality of our state-of-the-art products. Our services include design, development and installation, maintenance and technical support. We also offer solutions to many other tasks besides the ones introduced here.

BASICS OF INDUCTION HEATING

BASICS OF INDUCTION HEATINGUnique characteristics and basics of induction heating

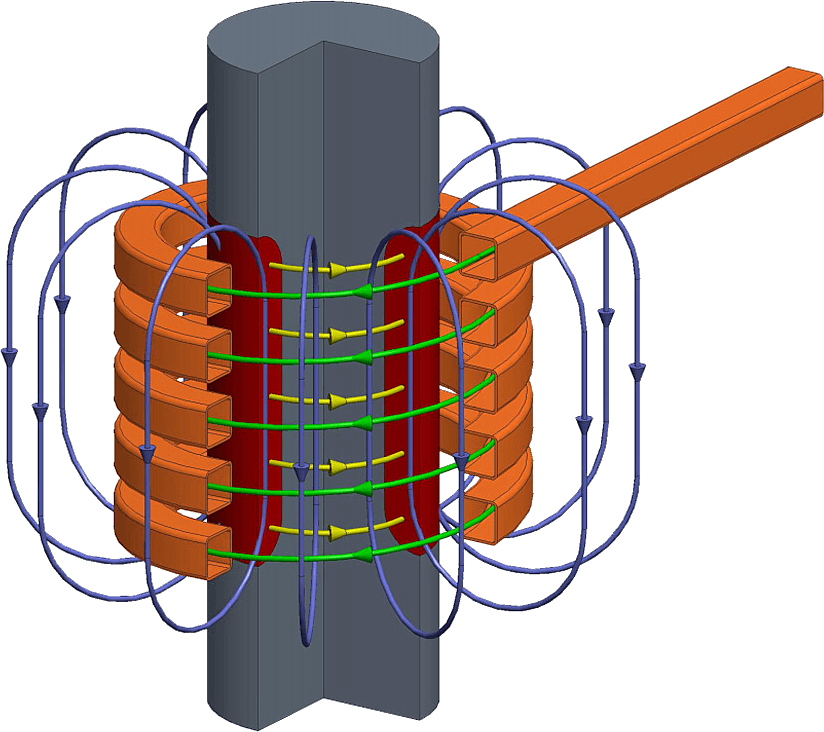

A periodic alternating current flowing in an electrical conductor creates an electromagnetic field. Placing another conductor within this space the electromagnetic field induces an alternating current. The delivery of energy is similar to that observed in transformers. In the case of induction heating the first conductor is the heating coil, which is the inductor, and the second conductor is the piece being worked on.

When the current in the inductor, placed near the work piece is the right frequency and amperage, the alternating current flowing through the piece heats it up. The extent of heating depends on the specific conductivity of the non-ferromagnetic pieces through which the current flows and on the diameter of the piece. In case of ferromagnetic materials the hysteresis heat resulting from periodic magnetism is added to this.