When using induction brazing we heat a pair of work pieces to brazing temperature and melt and solder the two together with a filler metal that was either put in place in advance or added gradually in a preheated state.

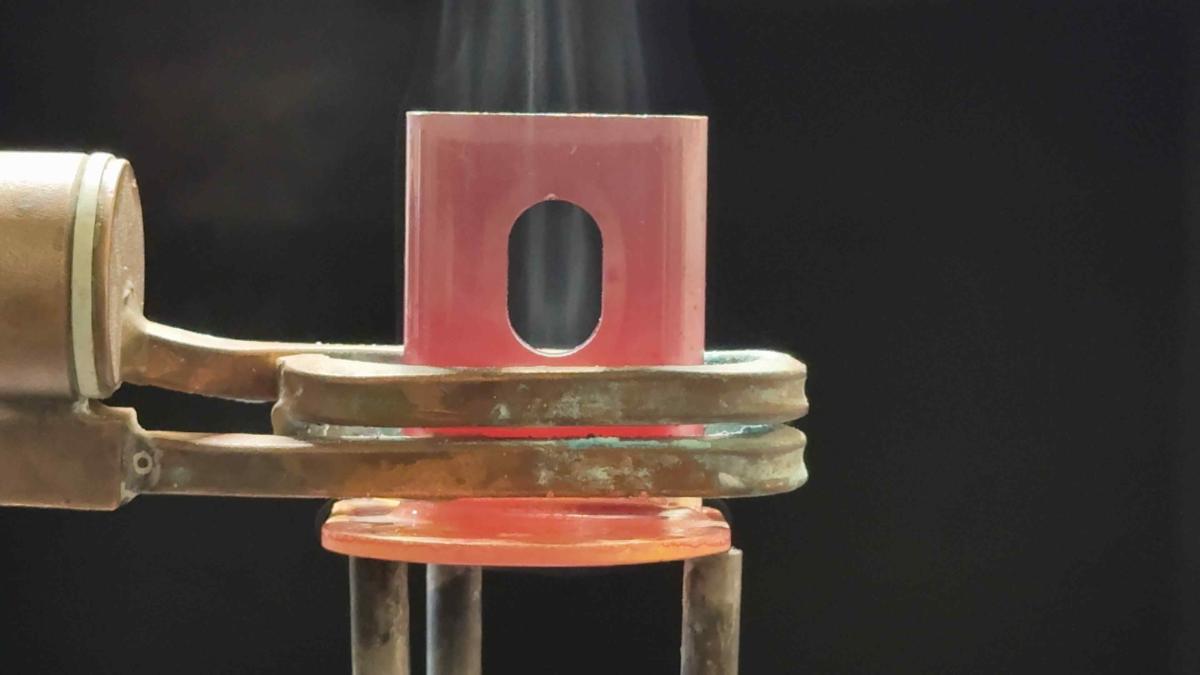

By developing the inductor to conveniently fit the desired purpose and by installing controls to regulate performance, we can ensure that the pieces being worked on will heat up simultaneously and the filler metal will be distributed evenly. The high density performance and maneuverability of induction heating as well as the use of a protective gas enables the industrial brazing of otherwise not easily soldered work pieces with a difficult geometry.

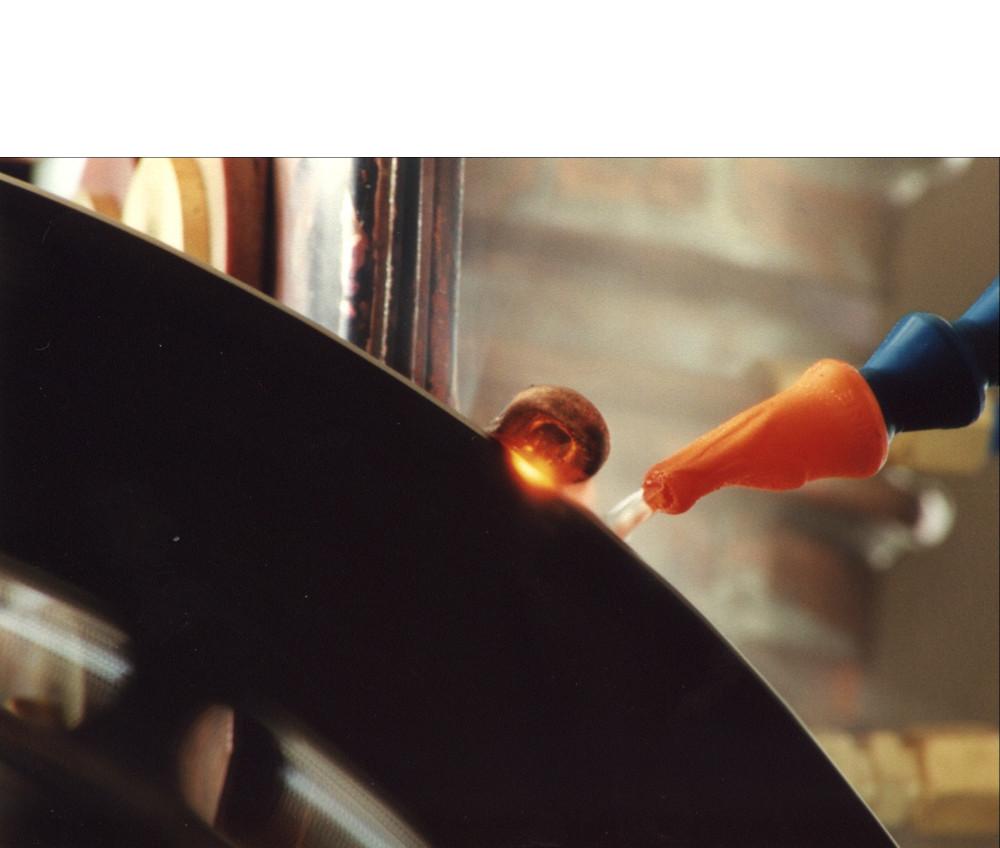

The handheld energy

The equipment can be universally utilized for soldering, brazing, heat treating, straightening, pre-heating for welding and numerous other special heating tasks. It can replace open flame heating in a fast, precise, economic way. The outstandingly small size and weight of the machine allows it to be used for continuous handheld operation. This is especially useful for tight, hard or reach spots, both in handheld operation mode, or by mounting it to a light robotic arm. The advanced, intelligent controller system makes it capable to manage complex heating procedures, whilst holding the process firmly under control.

The heating head:

The power supply unit:

The machines in this category are suitable for both soldering and brazing in power range 25 kW. Work pieces can be fed and positioned manually, but the brazers can be integrated into automated production lines as well. Their build makes them suitable for brazing a wide variety of sizes with different types of inductors, whether large and highly complex sets of parts need to be brazed in one step, or small segments onto large pieces locally, they can do the job.

The PLC program control unit enables the setting of different heating characteristics and workpiece cooling control.